Gun barrel measurement system

Home » Inspeksjonsutstyr » Gun Barrel Measurement

Gun barrel measurement & management system

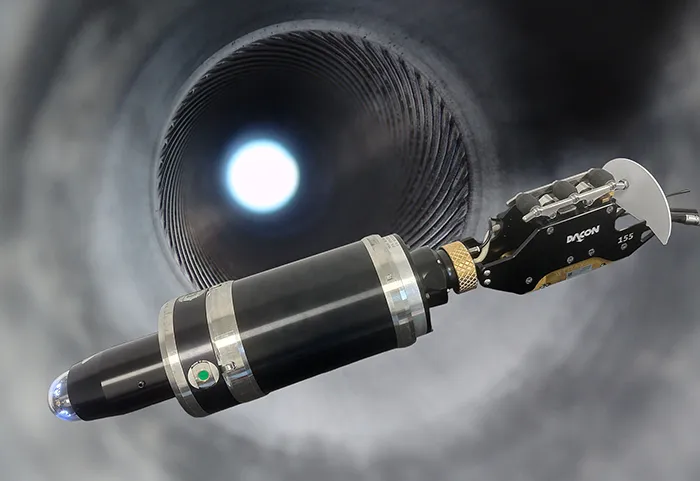

ROBINCA, a highly specialized tool for gun barrel condition monitoring, and Gun Barrel Management System (GBMS) is a database for logging and analysing of data.

Gun barrel wear managing has in the past been governed by very simple measures that have proven to be inadequate. The Norwegian DLO has seen the necessity to obtain better control over the degradation rate and mechanisms to provide good grounds for decision-making. Future weapon systems will face changing operational conditions and at the same time demands for cost reductions. This puts emphasis on thru life performance. It is desirable to determine what consequence gun barrel wear has for performance.

Quality assurance of manual recordings and logging of other relevant factors will contribute to optimal equipment efficiency. To encounter these challenges, Norwegian DLO has chosen to procure a highly specialized tool for gun tube condition monitoring as well as logging and analysis data processing system. The Norwegian DLO’s primary objective is to maintain accuracy, repeatability and flexibility – Managing all gun bores in the Norwegian army. The tool makes it possible to verify manufacturers’ data and performance for each barrel, management and cost optimizing for each individual gun and cannon as well as follow up specific tears and damages

Based on the Norwegian DLO’s achievement criteria (TDV018; inspection procedures for canon barrels established by the German Army regulation), ROBINCA is designed for maximum compliance with the inspection procedure and the ability to provide requested data quickly. The reports are input data for the analysis software.

The over all purpose for the ROBINCA method and technic is to apply value for the user by use of better methods. An effective monitoring of technical condition or RBI method can in our view provide significant improved safety and improved performance for military equipment as well as for other critical components within civil industry.

Safety for personnel and for equipment is for obvious reasons one vital factor. Also operational and economical advantages are important effects related to obtaining better control over the technical status of gun barrels: Knowledge of factors that affects precision, optimal lifespan utilization, better configuration management, quality control of user data and test and evaluation of new equipment are reported to be appreciated benefits among the specialist technicians and administrators at Norwegian DLO.